Best Molding Machine Types for Your Manufacturing Needs?

In the rapidly evolving manufacturing landscape, choosing the right molding machine is crucial for success. Industry expert John Smith once stated, "The right molding machine can transform production efficiency." His insight highlights the importance of selecting machines that fit specific production needs.

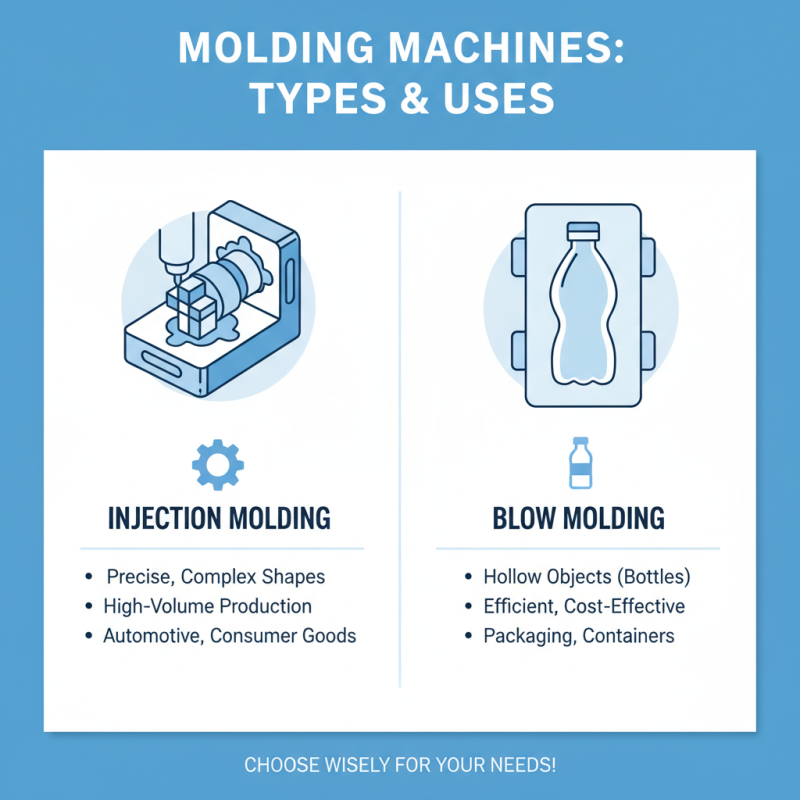

Various molding machine types exist, each designed for unique tasks. For instance, injection molding machines are perfect for producing complex shapes with precision. Blow molding machines excel in creating hollow objects like bottles. Understanding these options can significantly affect output quality.

However, navigating the choices can be overwhelming. Manufacturers often struggle with aligning machine capabilities to their specific requirements. It’s essential to reflect on production goals and evaluate machine features carefully. Time and effort spent in this phase can lead to improved productivity and efficiency in the long run.

Types of Molding Machines: An Overview of Options Available

When selecting a molding machine, understanding the types available is crucial. There are several options that cater to various manufacturing needs. Injection molding machines are popular for creating precise and complex shapes. They can produce large volumes with consistent quality, making them ideal for automotive and consumer products. Blow molding machines serve a different purpose, focusing on hollow objects like bottles. This process is efficient and cost-effective for mass production.

Thermoforming machines are another option. They heat plastic sheets and form them into desired shapes. This method suits packaging and disposable products. Research indicates that the global injection molding market was valued at over $200 billion in 2020, demonstrating its dominance in the industry.

Tips: Consider your product's design complexity when choosing a machine. A more complex design may require advanced technology and higher costs. Always analyze your production volume; high volumes may benefit from automated systems. Experimenting with different materials can also refine your choice. Remember, not every machine fits every need. Careful consideration is key for a successful investment.

Injection Molding Machines: Ideal for High-Volume Production

Injection molding machines are a staple in the manufacturing industry. These machines excel at creating high-volume products with precision. They are particularly effective for plastic parts, ensuring consistent quality and uniformity. This method is efficient, but it requires careful setup and calibration to achieve optimal results.

One of the challenges with injection molding is the initial cost. The machinery can be expensive, and the molding process can be complex. Not every manufacturing facility has the budget or expertise to handle these machines. It’s essential to weigh the benefits against potential drawbacks. Production can be quick, but initial runs often need adjustments.

Moreover, the choice of materials can limit designs. Some plastics work better than others. Researching material properties is crucial for achieving product goals. There’s always a learning curve when integrating new materials or adjusting machine settings. Despite the complexities, injection molding remains a powerful method for high-volume production, offering significant advantages for businesses ready to embrace its challenges.

Blow Molding Machines: Best for Hollow Plastic Products

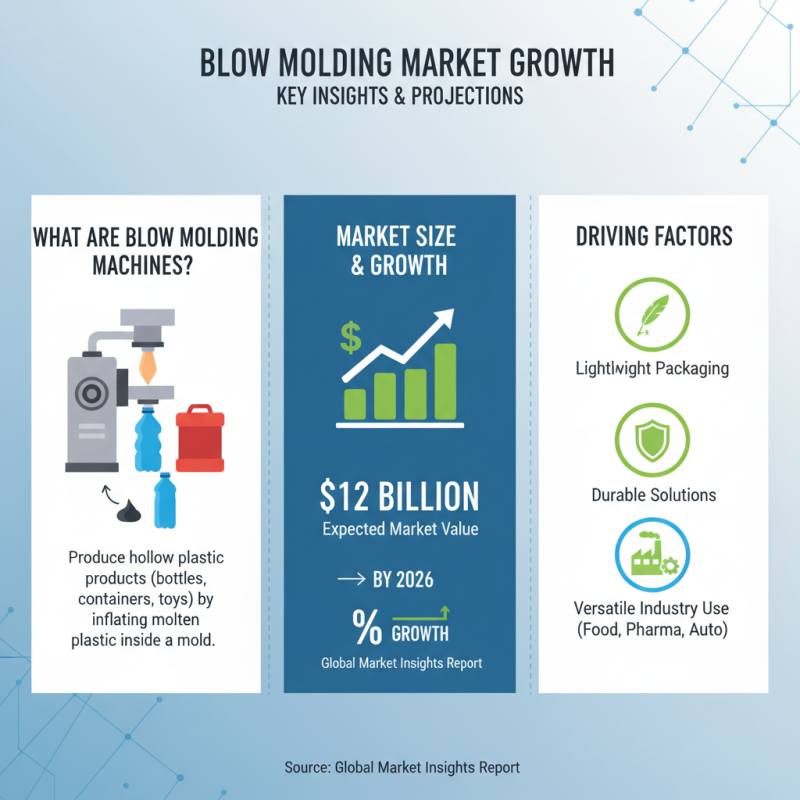

Blow molding machines are essential for producing hollow plastic products like bottles and containers. According to a report from Global Market Insights, the blow molding market is expected to surpass $12 billion by 2026. This growth reflects the rising demand for lightweight and durable plastic packaging solutions across various industries.

These machines operate by inflating hot plastic within a mold to create the desired shape. They offer high production rates and material efficiency. However, operators must monitor temperatures closely to avoid uneven flow. Common issues include uneven wall thickness and surface defects. A recent survey indicated that nearly 30% of manufacturers struggle with quality control, an area that deserves further attention.

The versatility of blow molding allows for various processes like extrusion and injection. Each method has its own merits and setbacks. For example, extrusion blow molding is ideal for creating larger products, while injection blow molding offers superior accuracy for smaller items. Yet, some facilities may lack the technical expertise or equipment to utilize these methods effectively. Understanding these trade-offs is crucial for manufacturers aiming to optimize their production lines.

Rotational Molding Machines: Versatile Solutions for Complex Shapes

Rotational molding machines have gained popularity in various manufacturing sectors. They offer remarkable flexibility for creating complex shapes. This method involves the use of heated molds that rotate slowly around multiple axes. The process ensures even distribution of material, which contributes to a high-quality finish. Manufacturers often turn to this technology for its ability to produce both large and small parts with intricate designs.

However, there are challenges to consider. The initial setup cost can be high, especially for custom molds. Production times may also be longer compared to other molding methods. Manufacturers must weigh these factors against the advantages of rotational molding. Additionally, achieving uniform wall thickness can sometimes be tricky, requiring a keen focus during production.

Despite these hurdles, the versatility of rotational molding machines is undeniable. They can be used for diverse applications, from automotive components to outdoor furniture. This adaptability speaks volumes about their value in today’s manufacturing landscape. It’s crucial to assess specific needs before making a decision.

Choosing the Right Molding Machine for Your Specific Manufacturing Needs

Choosing the right molding machine is crucial for your manufacturing needs. Each type of molding machine caters to specific production requirements. For instance, injection molding is ideal for high-volume production and intricate designs. Blow molding works best for hollow products, while compression molding is suitable for larger parts. According to a recent industry report, the global injection molding market is projected to reach $455 billion by 2026.

When selecting a molding machine, consider your production volume. For large-scale operations, high-speed machines may be more efficient. However, smaller manufacturers might benefit from versatile, lower-capacity machines that can adapt to different jobs. Assess the material types you'll use. Some machines are better for thermoplastics, while others are suited for elastomers.

Tips: Always evaluate the machine's energy efficiency. Higher efficiency can reduce operational costs. Additionally, think about maintenance and parts availability. A machine that's hard to service can lead to long downtimes. Reflect on your long-term needs and product demand. Choosing a machine based solely on initial cost might lead to higher expenses later. It's crucial to strike a balance between cost and capability.

Related Posts

-

How to Choose the Right Moulding Plastic Machine for Your Manufacturing Needs

-

Maximizing Production Efficiency with Advanced Plastic Molding Machines

-

Ultimate Injection Machine Comparison for Optimal Performance Selection

-

Understanding the Impact of Injection Molding Machines on Modern Manufacturing Efficiency

-

Top 10 Best Moulding Plastic Machines for Efficient Production

-

2025 Top Automatic Molding Machine Innovations for Efficient Production