Why Choose a Small Injection Machine for Your Manufacturing Needs?

In today's competitive manufacturing landscape, the choice of equipment is crucial. Many companies are turning to small injection machines for their production needs. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $283.9 billion by 2026. This growth emphasizes the importance of modern and efficient manufacturing tools.

Small injection machines offer unique advantages. Their compact size allows for flexibility in smaller production spaces. Moreover, they consume less energy, reducing overall operational costs. A study from Grand View Research indicates that energy-efficient machinery can cut costs by up to 30%. However, there are challenges. While they are efficient for small runs, they may not handle large-scale production well.

Choosing the right machinery involves trade-offs. Small injection machines excel in precision but may fall short in speed during high-demand scenarios. Manufacturers must weigh these factors carefully. In conclusion, investing in small injection machines can benefit many companies, but it requires a thoughtful approach to production goals.

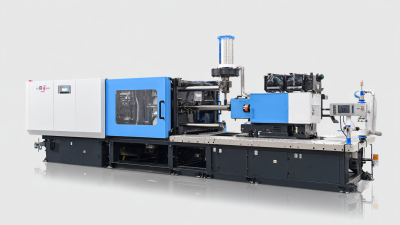

Advantages of Small Injection Machines in Precision Manufacturing

Small injection machines offer significant advantages in precision manufacturing. With their compact size, these machines excel at producing intricate parts. Reports indicate that small injection molding machines can achieve tolerances of ±0.01 mm, which is crucial for industries such as automotive and medical devices. This level of precision minimizes errors, ensuring high-quality outputs.

Furthermore, energy efficiency is another key benefit. Studies show that small injection machines use up to 50% less energy than larger models. This can lead to considerable cost savings over time. The reduced power consumption aligns with growing sustainability initiatives in manufacturing. However, some users might find the initial investment challenging. Balancing budget constraints with the desire for advanced technology often requires careful consideration.

Flexibility is another strong point of smaller machines. They can easily accommodate a variety of mold sizes, making them ideal for small production runs. However, scaling up production can pose challenges. Manufacturers must plan for the limitations in speed and output capacity. This balance between flexibility and efficiency remains a topic for ongoing reflection in the industry.

Cost-Effectiveness of Small Injection Machines Compared to Larger Models

Small injection machines have gained attention for their cost-effectiveness. They can produce quality parts at lower overhead costs. These machines require less energy, which can significantly reduce operating expenses over time. Maintenance costs are also lower compared to larger models. This is relevant for startups or companies with limited budgets.

Moreover, small injection machines occupy less space. This can be vital for smaller manufacturing facilities. Optimizing space utilization can lead to better workflow. However, potential buyers should carefully assess their production requirements. Smaller machines may not handle high-volume production efficiently, which could lead to longer lead times. Businesses must weigh their immediate needs against future growth plans.

In addition, it's essential to consider the initial investment. While small machines often have a lower price tag, the total cost of ownership is crucial. Hidden costs can arise from tooling and materials. This can diminish the advantages of choosing a smaller model. Understanding these factors can help manufacturers make informed decisions.

Market Trends: Growth of Small Injection Machine Usage in the Industry

The trend of using small injection machines in manufacturing is growing rapidly. Many industries recognize their efficiency and flexibility. These machines help in producing smaller parts with precision. This shift supports businesses in becoming more agile in their production processes.

Small injection machines save space. They can fit into smaller facilities without compromising performance. This makes them an attractive choice for startups and small enterprises. Additionally, these machines often have lower energy consumption. Manufacturers benefit from reduced operating costs.

**Tip:** When selecting a small injection machine, consider the material compatibility. Not every machine will work with all types of plastics.

The increasing demand for customized products pushes manufacturers to adopt small injection machines. They allow for quick changes in designs without significant downtime. However, businesses must evaluate their specific needs. Not all production lines will benefit equally.

**Tip:** Assess your production volume before investing. If your needs are low, a small machine might be ideal. If you do high volumes, think carefully about efficiency.

Efficiency and Energy Savings: Small Injection Machines in Production

Small injection machines are becoming a popular choice for manufacturers looking to enhance production efficiency. According to industry reports, these machines can reduce energy consumption by up to 40% compared to larger counterparts. This significant saving translates into lower operational costs and a smaller carbon footprint.

In addition, small injection machines use advanced technology to optimize the injection process. They require less material and are often designed for faster cycle times. Studies indicate that these machines can increase output by 30%, which allows production lines to respond quickly to market demands. Manufacturers can produce smaller batches without sacrificing quality or speed.

However, manufacturers must carefully assess their needs. Not all products may be suitable for small injection molds. There is a learning curve associated with maximizing efficiency. Continuous training and adaptation are essential. The investment in small machines should be evaluated against long-term production goals to ensure benefits outweigh initial challenges.

Why Choose a Small Injection Machine for Your Manufacturing Needs?

| Feature | Small Injection Machine | Standard Injection Machine |

|---|---|---|

| Initial Cost | Lower Cost | Higher Cost |

| Energy Consumption | 20% less | Standard |

| Footprint | Compact Design | Larger Footprint |

| Production Flexibility | Highly Flexible | Moderate Flexibility |

| Cycle Time | Faster | Standard |

| Maintenance Costs | Lower | Higher |

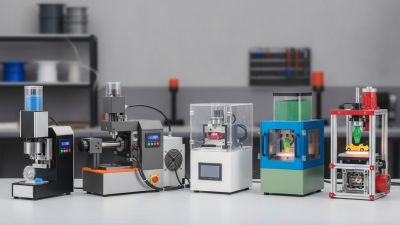

Customization and Versatility: How Small Injection Machines Meet Diverse Needs

Small injection machines are becoming popular choices in manufacturing. They offer outstanding customization and versatility. These machines can produce a wide range of items, from small parts to complex designs.

According to a recent industry report, the demand for small injection molding machines has increased by 25% in the past few years. This growth stems from manufacturers seeking cost-effective solutions. Smaller machines allow for quick adjustments, accommodating diverse production needs. They support rapid prototyping, enabling quicker market entries. This flexibility is crucial in today’s fast-paced manufacturing landscape.

**Tip:** Consider the specific needs of your production line. Different sectors, such as automotive or healthcare, may require unique features.

Small injection machines can produce various materials, including thermoplastics and elastomers. They cater to low and high-volume production. This adaptability is a game changer for manufacturers. However, it is important to assess the durability of machines. Investing in lower-quality models may lead to higher long-term costs.

**Tip:** Regular maintenance is essential. This practice ensures optimal performance and extends the equipment's lifespan.

Related Posts

-

Exploring the Comparative Benefits of Different Injection Molding Machine Types

-

Understanding the Different Types of Injection Molding Machines and Their Applications

-

7 Best Small Plastic Injection Machines for Efficient Production in 2023

-

How to Optimize Production Efficiency with Small Injection Molding Machines in Your Manufacturing Process

-

Top 5 Mini Plastic Injection Molding Machines You Should Consider

-

Top Small Plastic Injection Molding Machine Options for Your Business?