How to Choose the Right Type of Injection Molding Machine for Your Business

Choosing the right type of injection molding machine is critical for maximizing efficiency and profitability in manufacturing operations. According to the "Global Injection Molding Machine Market Report", the injection molding machine market is projected to reach USD 20 billion by 2026, with a compound annual growth rate (CAGR) of 4.5%. This growth underlines the increasing demand for tailored manufacturing solutions across various industries, including automotive, consumer goods, and medical devices.

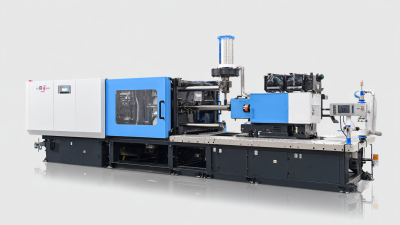

Selecting the appropriate types of injection molding machine not only optimizes production processes but also enhances quality and reduces waste. However, with the variety of machines available—ranging from hydraulic to electric models—it can be overwhelming for businesses to determine which type best fits their operational needs.

Careful consideration of factors such as material compatibility, production volume, and automation capabilities is essential to making an informed choice that aligns with strategic goals.

Choosing the right type of injection molding machine is critical for maximizing efficiency and profitability in manufacturing operations. According to the "Global Injection Molding Machine Market Report", the injection molding machine market is projected to reach USD 20 billion by 2026, with a compound annual growth rate (CAGR) of 4.5%. This growth underlines the increasing demand for tailored manufacturing solutions across various industries, including automotive, consumer goods, and medical devices.

Selecting the appropriate types of injection molding machine not only optimizes production processes but also enhances quality and reduces waste. However, with the variety of machines available—ranging from hydraulic to electric models—it can be overwhelming for businesses to determine which type best fits their operational needs.

Careful consideration of factors such as material compatibility, production volume, and automation capabilities is essential to making an informed choice that aligns with strategic goals.

Understanding the Different Types of Injection Molding Machines Available

Injection molding machines are essential for businesses in the manufacturing sector, providing efficiency and precision in producing parts and products. Understanding the different types available is crucial for making the right choice. Generally, there are two primary categories: standard and specialty machines. According to the Market Research Future report, the global injection molding machine market was valued at approximately $14.3 billion in 2020 and is projected to grow, indicating the increasing reliance on these machines across various industries.

Standard injection molding machines are ideal for producing high volumes of uniform products, making them a staple in industries like automotive and consumer goods. Conversely, specialty machines, such as multi-component or insert molding machines, cater to specific applications which require complex manufacturing processes. A study by Technavio highlights that the demand for multi-component injection molding machines is expected to rise significantly, estimated to witness an annual growth rate of over 5% through 2025. Selecting the appropriate machine type will ultimately depend on the production needs, material requirements, and technical specifications of your business.

Evaluating Your Production Volume and Business Needs

When selecting the appropriate type of injection molding machine for your business, evaluating your production volume and specific business needs is crucial. According to a report by Allied Market Research, the global injection molding machine market is projected to reach approximately $17 billion by 2027, indicating a significant demand across various industries. A key consideration is your production volume, which can greatly influence the type of machine you should invest in. For businesses anticipating high production rates, investing in larger, more automated machines can be beneficial, as they enhance efficiency and reduce cycle times.

Moreover, understanding your business needs goes hand in hand with production volume. For instance, if your focus is on smaller, specialized batches, a smaller, more versatile machine may suit your operations better. The same Allied Market Research report highlights that the growth of the automotive and consumer goods sectors is driving demand for machines with precision capabilities. This suggests that aligning your machine choice with industry trends and your specific application requirements—whether it’s large-scale production or customizable small runs—can help maximize productivity and ultimately improve profitability.

Key Features to Consider When Choosing an Injection Molding Machine

When selecting the right injection molding machine for your business, several key features must be considered to ensure optimal performance and efficiency. First and foremost, the clamping force is crucial. This parameter determines how tightly the mold is held shut during the injection process, directly impacting the quality and precision of the final product. If your products require higher precision or larger dimensions, you might need a machine with a higher clamping force.

Another significant aspect to evaluate is the injection speed and pressure. These factors influence how quickly and effectively the plastic material is injected into the mold cavity. Fast injection speeds are necessary for producing intricate designs and thin-walled components, while the capability to adjust injection pressure can help in achieving consistent quality across different production runs. Additionally, consider the machine's versatility, such as whether it can handle various materials or accommodate different mold sizes. This flexibility can be vital for adapting to changing market demands and expanding your product line.

Injection Molding Machine Features Comparison

Comparing Hydraulic, Electric, and Hybrid Injection Molding Machines

When selecting an injection molding machine, businesses must consider the three primary types: hydraulic, electric, and hybrid. Hydraulic machines are known for their robust performance and ability to handle large molds with high clamping forces. These machines are ideal for applications requiring significant pressure and high-speed production. However, they can be less efficient, consuming more energy and requiring more maintenance than their electric counterparts.

Electric injection molding machines, on the other hand, offer precision and energy efficiency. They are quieter, faster, and produce less waste, making them a popular choice for manufacturers focused on sustainability and cost-effectiveness. While the initial investment may be higher, the long-term savings in energy and maintenance can make electric machines more appealing, especially for productions with lower clamping force requirements.

Hybrid machines combine elements of both hydraulic and electric technologies, providing a balance of efficiency and power. They offer flexibility in production, allowing for both high-speed operations and the capability to handle larger molds. This versatility can be particularly beneficial for businesses that produce a wide range of products, as it enables them to adapt to different manufacturing needs without investing in multiple machines.

Budgeting for an Injection Molding Machine and Its Operational Costs

When budgeting for an injection molding machine, it’s essential to consider not only the initial purchase price but also the operational costs that will follow. The cost of machines can vary widely based on their size, type, and capabilities. Therefore, it is advisable to conduct thorough market research to determine what fits within your budget while meeting your production requirements. Don’t forget to account for financing options, which can alleviate the financial burden upfront but will add to long-term costs.

Operational costs encompass several factors, including maintenance, energy consumption, and raw materials. Regular maintenance is crucial to ensure the longevity and efficiency of the machinery, and it’s wise to set aside a budget for potential repairs. Additionally, energy consumption can significantly impact overall expenses, so selecting an energy-efficient model can lead to cost savings in the long run. Finally, fluctuations in raw material prices should be factored into your budgeting to avoid unexpected financial strain. Understanding these components will help you make a more informed decision that positively impacts your business’s bottom line.

Related Posts

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights

-

Global Quality Revolution How Chinese Moulding Plastic Machines Capture International Markets

-

Exploring Innovative Alternatives to Plastic Injection Machines for Modern Manufacturing

-

Exploring the Comparative Benefits of Different Injection Molding Machine Types

-

Understanding the Different Types of Injection Molding Machines and Their Applications

-

Ultimate Injection Machine Comparison for Optimal Performance Selection