Why Electric Injection Molding Machines Are Revolutionizing Manufacturing Efficiency

The rise of the electric injection molding machine is transforming the landscape of manufacturing, presenting a myriad of efficiency benefits that are hard to ignore. According to a report by the Plastic Industry Association, the global market for electric injection molding machines is projected to reach $4.5 billion by 2025, driven by their ability to provide higher precision, faster cycle times, and lower energy consumption compared to their hydraulic counterparts.

With energy costs becoming a critical concern for manufacturers, electric machines offer up to 70% less energy consumption, allowing companies to not only enhance their sustainability efforts but also reduce operating costs. Moreover, the precision control facilitated by electric systems is leading to improved product quality and reduced scrap rates, further pushing manufacturers towards adopting this innovative technology.

As the industry embraces these advancements, electric injection molding machines are undoubtedly revolutionizing manufacturing efficiency, paving the way for a smarter and more sustainable future in production processes.

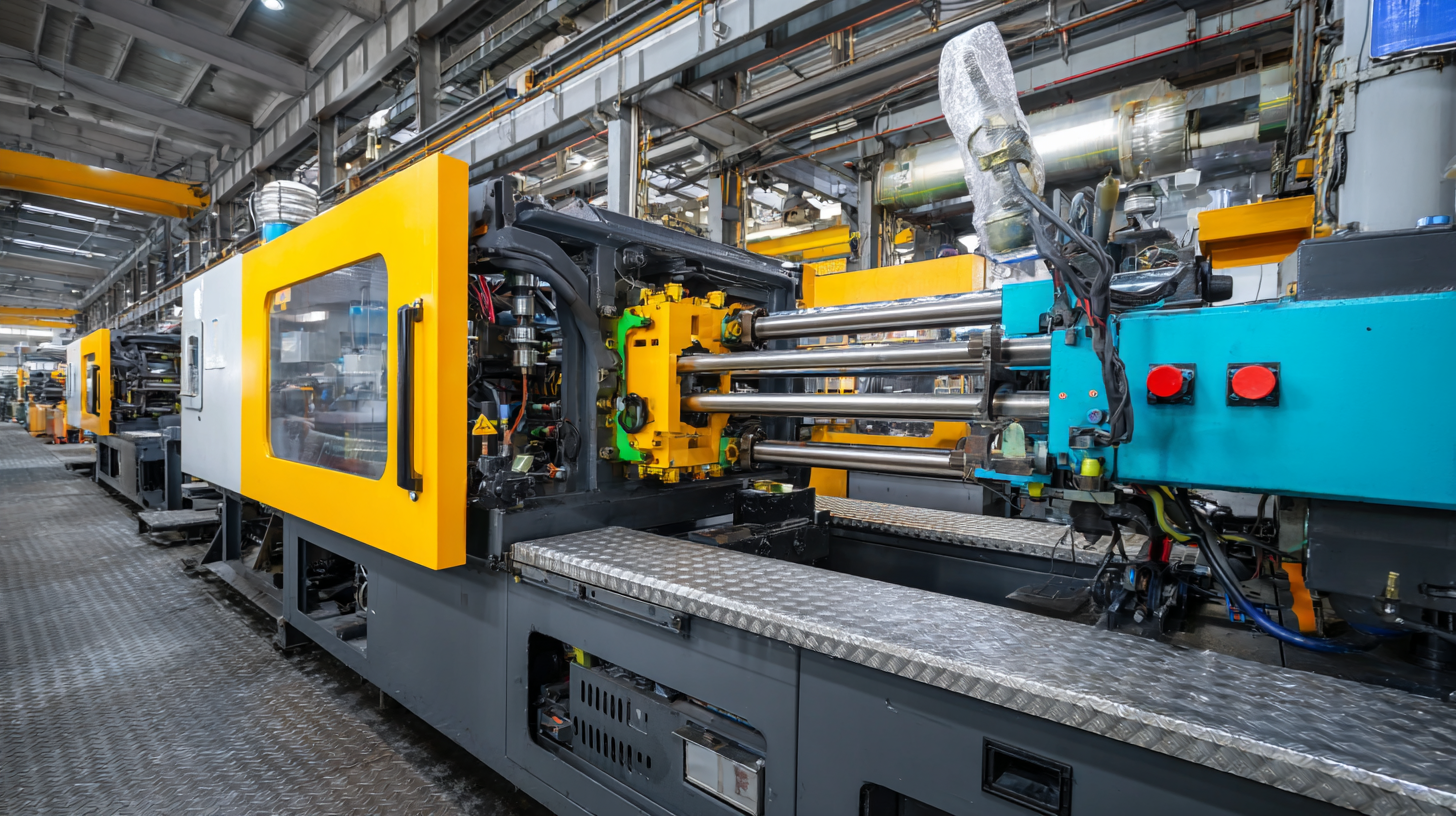

The Shift from Traditional to Electric Injection Molding Machines

The transition from traditional hydraulic injection molding machines to electric alternatives marks a significant evolution in manufacturing. Traditional machines rely on hydraulic systems that consume considerable energy and can lead to fluctuating performance levels, which may compromise product quality. In contrast, electric injection molding machines utilize servo motors and advanced controls, ensuring precise movements and consistent pressure throughout the molding process. This shift not only enhances the quality of the final product but also increases the overall efficiency of production lines.

Furthermore, electric machines are designed with sustainability in mind. They operate with lower energy consumption, often reducing energy costs by 30-70% compared to their hydraulic counterparts. This not only makes them more environmentally friendly but also appeals to businesses striving to reduce their carbon footprint. As manufacturers increasingly prioritize efficiency and sustainability, the adoption of electric injection molding machines is expected to become more commonplace, enabling a new era of production that aligns with modern industry demands.

Why Electric Injection Molding Machines Are Revolutionizing Manufacturing Efficiency

This chart illustrates the improvement in manufacturing efficiency when comparing traditional hydraulic injection molding machines to electric injection molding machines over time. The data shows a significant reduction in cycle time and energy consumption, highlighting the advantages of electric technology in modern manufacturing.

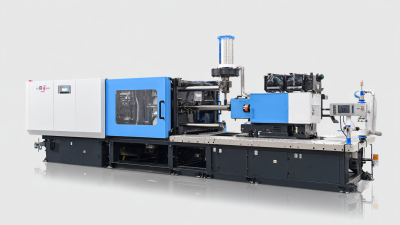

Enhancing Production Speed and Precision with Electric Technology

Electric injection molding machines are at the forefront of technological advancements in manufacturing, significantly enhancing production speed and precision. Unlike their hydraulic counterparts, electric machines utilize servo motors to control the injection process, enabling faster cycle times and reducing the overall manufacturing footprint. This improved speed not only allows manufacturers to produce more parts in a shorter timeframe but also minimizes energy consumption, contributing to a more sustainable production approach.

Furthermore, electric technology brings unparalleled precision to the injection molding process. With advanced feedback systems, these machines can make real-time adjustments to pressure and temperature, ensuring consistent part quality and reducing defects. The precise control over the injection process leads to higher dimensional accuracy, which is critical for industries requiring stringent tolerances. As a result, manufacturers can meet the growing demands for high-quality components without compromising on efficiency. This combination of speed and precision positions electric injection molding machines as a game-changer in modern manufacturing.

Environmental Benefits of Electric Injection Molding Machines

Electric injection molding machines are transforming the manufacturing landscape, particularly in terms of their environmental benefits. Unlike traditional hydraulic machines that utilize oil for operation, electric machines run on electric power, significantly reducing energy consumption and carbon emissions. This shift not only minimizes the ecological footprint of production processes but also aligns with global sustainability goals. The reduction in energy usage leads to lower operational costs, making these machines an attractive investment for manufacturers looking to improve both their profitability and environmental impact.

Moreover, electric injection molding machines produce less waste, contributing to a cleaner manufacturing environment. Their precision and reduced cycle times mean that less material is wasted during production, and the ability to mold complex shapes efficiently results in fewer defects. Additionally, the incorporation of advanced technology in these machines enhances recyclability by allowing manufacturers to easily adjust production to accommodate recycled materials. By embracing electric injection molding, companies can lead the charge toward a more sustainable future, benefitting not just their bottom line but also the planet.

Why Electric Injection Molding Machines Are Revolutionizing Manufacturing Efficiency - Environmental Benefits of Electric Injection Molding Machines

| Dimension | Electric Injection Molding Machines | Hydraulic Injection Molding Machines |

|---|---|---|

| Energy Efficiency | 30-50% less energy consumption | Higher energy consumption |

| Cycle Time | Reduced cycle time by 20% | Longer cycle times |

| Waste Production | Less plastic waste | More plastic waste |

| Noise Levels | Quieter operation | Louder operation |

| Maintenance | Lower maintenance costs | Higher maintenance costs |

Cost Efficiency: Lower Operating Costs and Higher ROI

Electric injection molding machines are setting a new standard in manufacturing efficiency, primarily through enhanced cost efficiency and ROI. The adoption of these advanced machines minimizes operating costs significantly. With lower energy consumption and reduced labor inputs, manufacturers can optimize production processes, achieving higher productivity levels without proportionately increasing expenses. Additionally, the capability for faster cycle times allows for a greater volume of products to be produced, directly impacting profitability.

Tips for Reducing Operating Costs:

- Invest in automation alongside electric injection molding machines to further streamline production and minimize labor costs.

- Regularly conduct cost-benefit analyses to benchmark ROI, ensuring that machine performance aligns with financial goals.

- Leverage data analytics to monitor machine utilization and maintenance schedules, preventing downtime and maximizing operational efficiency.

The integration of electric injection molding with machine learning technologies is further enhancing profitability. By analyzing data collected from production processes, manufacturers can identify inefficiencies and defects, allowing for timely adjustments that prevent costly errors. This combination of technologies not only drives down costs but also fosters a culture of continuous improvement within manufacturing operations.

Future Trends in Electric Injection Molding and Manufacturing Innovations

As the electric injection molding market continues to evolve, it is expected to reach a value of $1.595 billion in 2024, growing to approximately $2.838 billion by 2032, with a compound annual growth rate (CAGR) of 7.47%. This growth is underscored by a shift towards more sustainable and efficient manufacturing processes, with electric machines gaining prominence over their hydraulic counterparts.

One notable development is the opening of a new integrated factory in Jiaxing, which signifies a commitment to enhancing operational capabilities and production efficiency. This strategic move reflects the current trend of manufacturers investing in advanced technologies that not only improve output but also minimize environmental impact.

**Tip**: Manufacturers considering the switch to electric injection molding machines should evaluate their current production demands and explore energy-efficient options to leverage significant cost savings in the long run.

As showcased at the CHINAPLAS 2024 International Rubber and Plastics Exhibition, the focus on innovation is palpable. The event promises to highlight cutting-edge advancements throughout the industry, indicating that the future of injection molding will likely feature increasingly sophisticated technologies that prioritize both efficiency and sustainability.

**Tip**: Keeping abreast of trends showcased at industry exhibitions can provide essential insights into competitive strategies and emerging technologies that could benefit your manufacturing operations.

Related Posts

-

How to Choose the Best Home Plastic Injection Molding Machine for Your DIY Projects

-

Understanding the Different Types of Injection Molding Machines and Their Applications

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights

-

Maximizing Production Efficiency with Advanced Plastic Molding Machines

-

Exploring the Comparative Benefits of Different Injection Molding Machine Types

-

7 Best Small Plastic Injection Machines for Efficient Production in 2023