Understanding the Different Types of Injection Molding Machines and Their Applications

In the world of manufacturing, injection molding plays a crucial role in producing a diverse range of plastic products. Understanding the different types of injection molding machines is essential for industry professionals to select the most suitable equipment for their specific applications. From standard hydraulic machines to advanced electric and hybrid models, each type offers unique benefits and functionalities tailored to various production needs. This blog will delve into the best types of injection molding machines, exploring their operational mechanisms, strengths, and ideal use cases. By comprehending these distinctions, manufacturers can optimize their production processes, enhance efficiency, and ultimately ensure the quality of their end products. Join us as we uncover the intricacies of injection molding technology and its wide-ranging applications across different sectors.

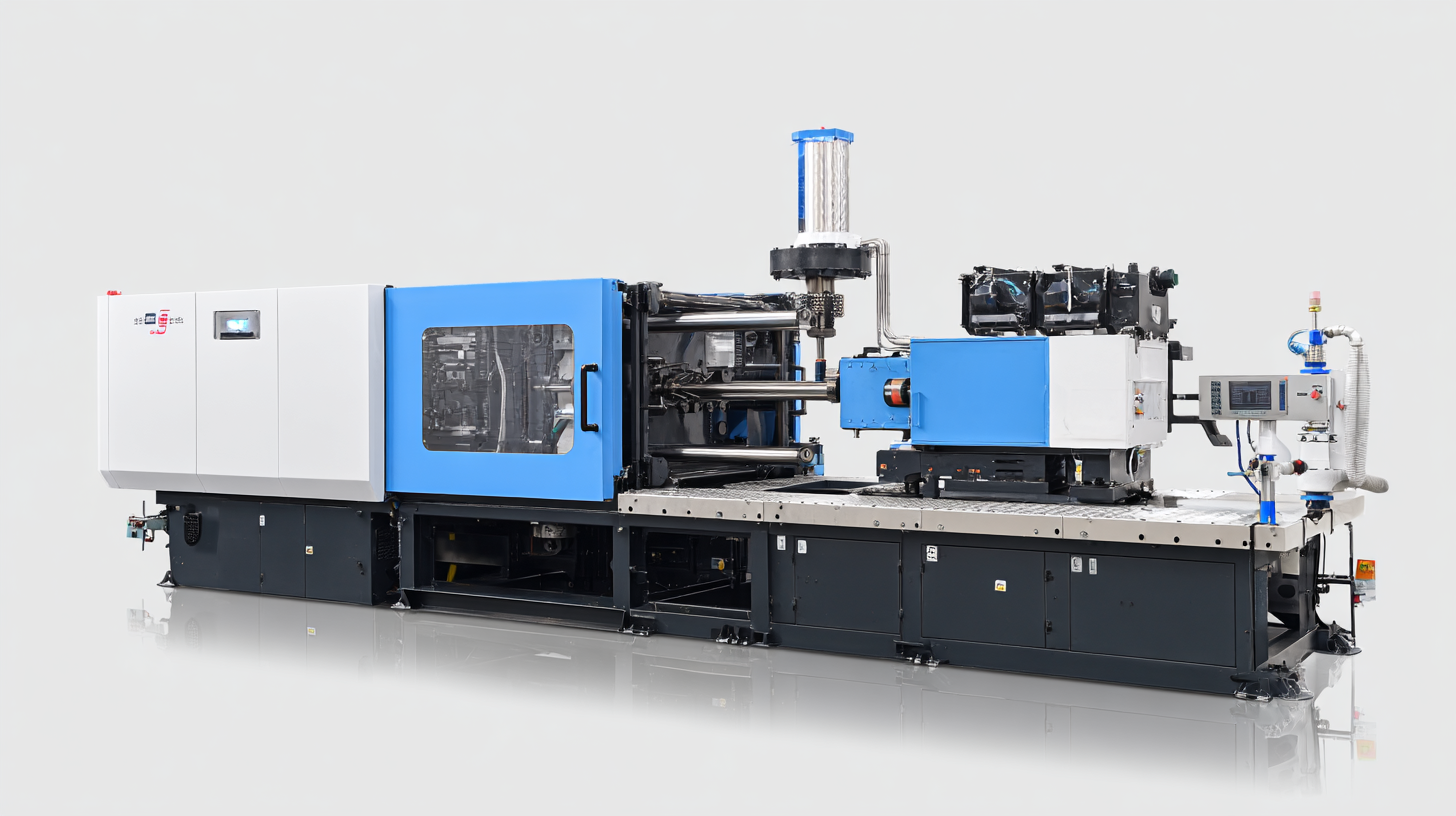

Types of Injection Molding Machines: An Overview of Their Functionality

Injection molding machines are essential in the manufacturing process, specifically for producing plastic parts in high volumes. Understanding their different types is crucial for industries looking to optimize production. The primary classification of injection molding machines includes hydraulic, electric, and hybrid systems. Hydraulic machines, widely used due to their robust performance, rely on hydraulic fluids for the injection process. They are ideal for large-scale production and high-pressure applications, making them a preferred choice for heavy-duty manufacturing.

Injection molding machines are essential in the manufacturing process, specifically for producing plastic parts in high volumes. Understanding their different types is crucial for industries looking to optimize production. The primary classification of injection molding machines includes hydraulic, electric, and hybrid systems. Hydraulic machines, widely used due to their robust performance, rely on hydraulic fluids for the injection process. They are ideal for large-scale production and high-pressure applications, making them a preferred choice for heavy-duty manufacturing.

Electric injection molding machines, on the other hand, are gaining popularity for their energy efficiency and precision. They utilize electric servos to control the injection process, resulting in reduced energy consumption and lower operational costs. These machines are particularly suitable for producing small to medium-sized parts requiring high accuracy and repeatability. Additionally, hybrid machines combine the best features of both hydraulic and electric systems, offering flexibility and efficiency. By understanding the functionality of these different types, manufacturers can select the most appropriate machine for their specific applications, enhancing productivity and reducing costs in their production lines.

Hydraulic vs. Electric Injection Molding Machines: Key Differences Explained

When it comes to injection molding, choosing the right type of machine is crucial for optimized production efficiency and product quality. Hydraulic and electric injection molding machines are the two main categories, each with distinct advantages tailored for specific applications. According to a 2022 market report from Grand View Research, the global electric injection molding machine market was projected to reach $5.2 billion by 2027, fueled by increasing demand for energy-efficient production processes.

Hydraulic machines are known for their robust strength and ability to handle large, complex molds, making them ideal for applications in the automotive and packaging sectors. They utilize hydraulic fluid to generate force, allowing for higher clamping pressure and faster cycle times. However, their energy consumption is typically higher, with reports indicating that hydraulic systems can consume up to 30% more energy compared to their electric counterparts.

On the other hand, electric injection molding machines offer superior precision and lower operational costs due to their energy efficiency and reduced maintenance requirements. A study by Technavio revealed that electric machines can reduce energy consumption by up to 70%, making them a popular choice for high-precision industries such as electronics and medical devices. As manufacturers increasingly focus on sustainability and operational efficiency, the trend towards electric machines continues to gain momentum in the injection molding sector.

Understanding the Different Types of Injection Molding Machines and Their Applications

| Type | Drive System | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Injection Molding Machine | Hydraulic | Large-scale parts, automotive components, industrial applications | High clamping force, excellent repeatability | Higher energy consumption, less precision |

| Electric Injection Molding Machine | Electric servo motor | Precision parts, medical devices, electronic components | Lower energy consumption, high precision, quieter operation | Higher initial cost, may have limitations on part size |

| Hybrid Injection Molding Machine | Combination of hydraulic and electric | Versatile applications, suitable for a range of part types | Balanced performance, flexibility in production | More complex maintenance, potential cost concerns |

Common Applications for Each Type of Injection Molding Machine

Injection molding machines play a crucial role in manufacturing diverse plastic products tailored for various applications. Each type features unique characteristics that make it suitable for specific tasks. For instance, hydraulic injection molding machines are renowned for their powerful clamping force, making them ideal for producing large and complex parts, such as automotive components and industrial equipment. Their versatility allows manufacturers to handle different materials effectively, enhancing productivity in large-scale operations.

On the other hand, electric injection molding machines have gained popularity due to their precision and energy efficiency. These machines are particularly beneficial for projects requiring rapid production cycles and high accuracy, making them a popular choice for producing consumer goods like electronic casings and medical devices. Additionally, hybrid injection molding machines combine the benefits of both hydraulic and electric systems, offering improved performance for medium-sized projects where precision and power are equally important. This adaptability makes hybrid machines vital in industries ranging from healthcare to packaging, ensuring high-quality outputs tailored to market demands.

Factors to Consider When Choosing an Injection Molding Machine

When choosing an injection molding machine, several crucial factors should be considered to ensure optimal performance and efficiency. One primary aspect is the type of material to be used, particularly thermoplastics, which are commonly utilized in various applications. According to industry reports, the demand for thermoplastics in healthcare is anticipated to grow significantly, driven by the need for lightweight, durable, and biocompatible materials. Factors such as environmental impact, end-use conditions, and specific mechanical properties should guide the selection process. For instance, materials that offer resistance to sterilization techniques and chemical agents are essential for medical device manufacturing.

Another important consideration is the machine's capabilities, including clamping force, cycle time, and energy efficiency. Advanced injection molding machines can significantly influence production costs and product quality. Reports indicate that the integration of smart technologies in molding machines enhances monitoring capabilities and reduces downtime. Additionally, the choice of machine should align with production scale; for high-volume operations, investing in machines with fast cycle times and high precision can yield significant long-term savings and improved profitability. By addressing these factors, manufacturers can select injection molding machines that best fit their operational needs and industry standards.

Future Trends in Injection Molding Technology and Its Impact on Industry

The injection molding industry is undergoing significant transformations driven by advances in technology and materials. Recent reports indicate that by 2024, the added value of China's larger-scale machinery industry is expected to grow by 6.0% compared to previous years. The increased emphasis on sustainability and efficiency has led to the emergence of innovative injection molding techniques, such as the use of modern materials that enhance product performance while reducing environmental impact.

As we look ahead, the market for metal injection molding (MIM) is projected to see substantial growth, driven by its applications in various industries, including aerospace and automotive. By 2032, the MIM market size is anticipated to expand significantly, reflecting the demand for complex and precise components that traditional manufacturing methods struggle to produce. Industry advancements, such as the 800G LENS technology, are expected to push the boundaries of design flexibility and performance, ultimately reshaping how plastic components are utilized in engineering applications. The evolution of injection molding technology not only highlights its critical role in manufacturing but also signals a shift toward more innovative production solutions tailored for the future.

Related Posts

-

Exploring the Comparative Benefits of Different Injection Molding Machine Types

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights

-

Maximizing Production Efficiency with Advanced Plastic Molding Machines

-

Ultimate Injection Machine Comparison for Optimal Performance Selection

-

How to Choose the Best Home Plastic Injection Molding Machine for Your DIY Projects

-

Exploring Innovative Alternatives to Plastic Injection Machines for Modern Manufacturing