How to Use Liquid Sulphur Black in Industries?

liquid sulphur black is a versatile chemical used across various industries. Its applications range from textiles to agriculture. As industries seek efficient solutions, this product stands out for its effectiveness.

In textile manufacturing, liquid sulphur black acts as a dye. It provides deep, rich colors to fabrics, enhancing their appeal. This pigment is often favored for its durability. However, achieving the perfect shade can be challenging. Each batch can vary, requiring careful adjustments.

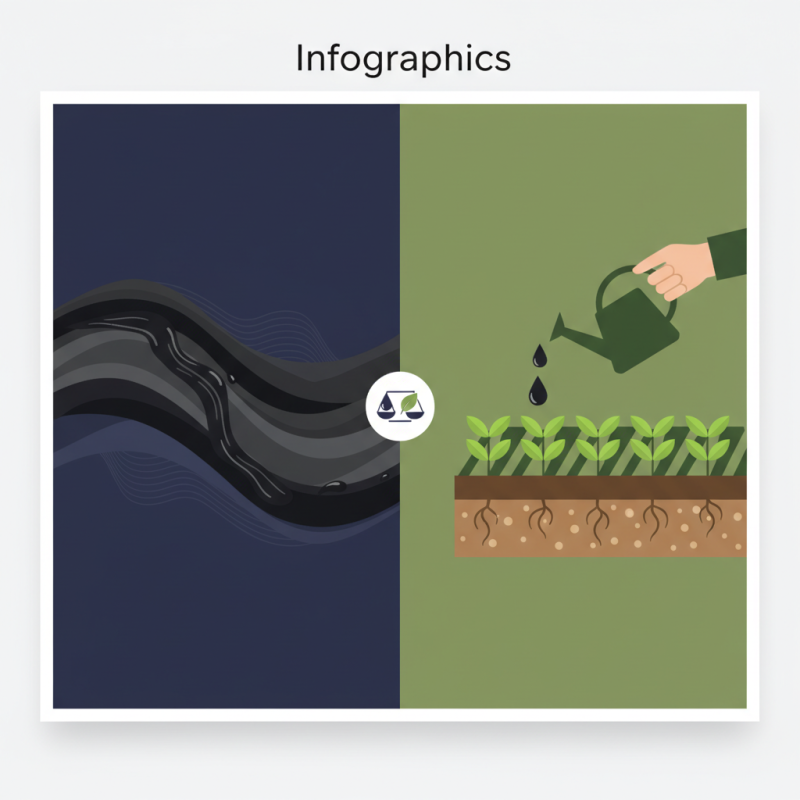

In agriculture, liquid sulphur black serves as a vital component in fertilizers. It helps improve soil quality and crop yield. Farmers depend on it for healthier plant growth. Yet, overuse can lead to soil imbalances. Striking a balance is essential for sustainable practices. This complexity highlights the need for responsible use in all applications.

Understanding Liquid Sulphur Black: Properties and Benefits

Liquid Sulphur Black is gaining attention in various industries. Its unique properties make it a versatile choice for manufacturing. This liquid form enhances its ease of use, improving efficiency in production processes. Many industries rely on this compound for its ability to provide deep, rich colors.

The properties of Liquid Sulphur Black are impressive. It offers excellent colorfastness and high stability. This makes it a preferred option for textiles and coatings. Its low toxicity and environmental friendliness are added benefits. However, users must understand proper handling to avoid potential risks.

Tips: Always store Liquid Sulphur Black in a cool, dry place. Use appropriate personal protective equipment during handling. Test small batches first to ensure compatibility with other materials. Such precautions can prevent mishaps and enhance safety.

Despite its advantages, some challenges arise. Not all materials react well with this compound. Testing is crucial. Users should be cautious and modify processes as needed. Overall, Liquid Sulphur Black holds significant promise, but careful consideration is essential.

Usage of Liquid Sulphur Black in Various Industries

Applications of Liquid Sulphur Black in Various Industries

Liquid sulphur black is increasingly popular across various industries due to its versatile applications. In the textile industry, it serves as a cost-effective dye for achieving deep black hues on fabrics. The textile sector utilizes it extensively, with recent reports suggesting that the global market for textile dyes is expected to reach $20 billion by 2025. This growth illustrates the rising demand for reliable, high-quality dyes like liquid sulphur black.

In agriculture, liquid sulphur black plays a critical role. It is used as a soil amendment to improve its properties. Many farmers have reported enhanced crop yields after adding it to their soil management practices. Studies show that proper soil treatment can increase productivity by up to 30%. This highlights the significance of using liquid sulphur black correctly, although some may overlook its environmental impact under specific conditions.

The rubber industry also benefits from liquid sulphur black, utilizing it as a reinforcing agent. It enhances the strength and durability of rubber products. However, the optimization of its use is often neglected. Data indicates that improper formulation can lead to decreased performance and product failure. A balance between performance enhancement and environmental safety is crucial for sustainable progress in these industries.

Guidelines for Safe Handling and Storage of Liquid Sulphur Black

Liquid Sulphur Black is widely used in industries such as textiles and agriculture. However, handling this chemical safely is crucial. The material safety data sheets (MSDS) provide clear guidelines. These documents highlight that Liquid Sulphur Black can cause skin irritation and respiratory issues if improperly managed.

When transporting and storing Liquid Sulphur Black, ensure that containers are tightly sealed. Maintain storage areas in cool, dry locations away from direct sunlight. According to industry reports, around 30% of chemical-related accidents occur due to poor storage practices. Regular training sessions for employees can significantly lower these risks.

PPE, such as gloves and masks, should be mandatory when working with this substance. The American Chemical Society suggests that eye protection is also vital. Despite these precautions, some workers overlook safety measures. It's essential to review and reinforce safety protocols regularly to prevent negligence that could lead to serious incidents.

How to Use Liquid Sulphur Black in Industries? - Guidelines for Safe Handling and Storage of Liquid Sulphur Black

| Dimension | Details |

|---|---|

| Chemical Name | Liquid Sulphur Black |

| CAS Number | 10034-99-8 |

| Usage | Textile dyeing, polymer coloring, and industrial applications |

| Storage Temperature | 15°C to 25°C |

| Safe Handling | Use PPE, avoid contact with skin and eyes |

| Spill Response | Contain spill, use inert materials for absorption |

| Disposal Methods | Dispose according to local regulations |

Top Tips for Incorporating Liquid Sulphur Black in Manufacturing Processes

Liquid sulphur black is an important component in various industrial applications. Its use enhances colorfastness and durability in textiles and coatings. To effectively incorporate it into manufacturing, consider a few practical tips.

Begin by understanding the proper mixing ratios. Too much liquid sulphur black can lead to uneven coloration. Always test small batches before scaling up. This practice helps prevent waste and ensures consistent quality. Keep an eye on the temperature during the mixing process. High temperatures can cause unexpected reactions that may compromise the product.

Another crucial tip is to maintain safety protocols. Liquid sulphur black can be hazardous if ingested or inhaled. Personal protective equipment is essential. Establish clear guidelines for handling this substance. It’s easy to overlook safety when focusing on productivity, but neglecting it can lead to serious accidents. Regular training sessions can reinforce safe handling practices and keep workers aware of potential risks.

Regulatory Compliance and Environmental Considerations for Liquid Sulphur Black

Liquid Sulphur Black is gaining popularity in industries for its diverse applications. However, using this substance requires strict adherence to regulatory compliance and environmental considerations. Companies must navigate complex regulations that govern the use of such chemicals. Failure to comply can lead to significant penalties and damage to reputation.

Many industries are under constant scrutiny regarding their environmental impact. Liquid Sulphur Black, if not handled correctly, can pose risks to ecosystems. It’s essential to ensure proper waste disposal methods and to monitor emissions during the production process. Regular audits should be part of the operational protocol to maintain compliance. Moreover, training employees on safe handling practices is crucial.

Despite the benefits of using Liquid Sulphur Black, some challenges remain. Industries need to invest in better technology to minimize environmental impact. There is always room for improvement in waste management strategies. Engaging with local communities can provide valuable insights into environmental concerns. Ultimately, being proactive about compliance and sustainability will pave the way for responsible use of Liquid Sulphur Black.